checklist for the design of large belt conveyor systems

Checklist Conveyors PDF Belt (Mechanical) Equipment - Scribd

Checklist Conveyors PDF Belt (Mechanical) Equipment. Checklist Conveyors - Free download as Word Doc (.doc), PDF File (.pdf), Text File (.txt) or read online for free.

Conveyor Belts Systems: Design Manufacturing

Details Troughed Belt Conveyors Open troughed belt conveyors transport bulk goods, e.g. for cement manufacture, quickly across large distances and rough terrain. Details Pipe Conveyors A pipe conveyor is

DESIGN OF MATERIAL HANDLING EQUIPMENT: BELT CONVEYOR SYSTEM

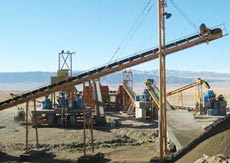

The design of a belt conveyor system takes into account the followings: A. Dimension, capacity and speed B. Roller diameter C.Belt power and tension D.Idler spacing E. Pulley diameter F. Motor G. Type of drive unit H. Control mode Figure 1: Belt Conveyor Figure 2: CATIA Design of Belt Conveyor Belt Dimension, Capacity and Speed

ALLIANZ GLOBAL CORPORATE SPECIALTY® CONVEYOR SYSTEMS

AT-A-GLANCE. Conveyor systems are commonly used because of their efficiency in transporting products between different areas. The hazards associated with conveyor systems consist not only of the transported material and structure, but also the conveyor itself. An automatic fire protection system should be installed over most conveyor systems.

Metal Belt Conveyor System Design Checklist for

2016.5.13 Whether you are seeking an entirely new food processing conveyor system or to upgrade an existing system for increased safety and product quality, Belt Technologies is able to help.

What is Conveyor System? Types, Parts, Working, Uses [PDF]

2021.8.10 Disadvantages of Conveyor System. Following are the disadvantages of conveyor system: The general design of the belt conveyor is opened. So there is a possibility of product fall. If you need to install covers, it can be expensive. Sticky material can become trapped on the belt and transfer to the return side, roll, idler, and pulley.

IS 11592 (2000): Selection and Design of Belt Conveyors - Code

NOTE — The troughed angle of 15° is applicable for 2-roll belt conveyors only. 4.2.1 For return idlers, the troughing angle of 0°, 10°, or 15°, shall preferably be adopted. 4.3 Flat belt conveyor is that in which the belt runs flat on the carrying side, over an idler or a

6 key considerations for conveyor selection - Processing

Breakthrough Products Awards. Maintenance Safety. Mixing Blending. Powder Bulk Processing. Process Control Automation. Pumps, Motors Drives. Valves Actuators. Proper selection and sizing is critical to successfully meeting production goals in a batch or continuous processing application.

(PDF) Best Practices on Conveyor Safety - ResearchGate

2015.6.3 Appendix D Conveyor System Safety Checklist 74. ... belt conveyor systems in Alberta. Note: Design, maintenance and repair of conveyor systems are not within the scope of this guide. 7.

Best Practice: Conveyor Belt Systems - MHSC

Figure 1: Conveyor accidents recorded in SA mining industry (1988-1999) 13 Figure 2: Accidents traceable to specific conveyor sub-systems (1995-1999) 14 Figure 3: Man on conveyor belt performing maintenance after locking out 38 Figure 4: Effective guarding around drive pulley 38 Figure 5: Walkway with restricted access 39

VWHPV - IOPscience

Belt Conveyor's Drive System in Industrial Conditions Robert Król, Damian Kaszuba and Waldemar Kisielewski-Loose Material Filling in the Loading Trough Profile of the Belt Conveyor Leopold Hrabovský-Design of Belt Conveyor Speed Control System of Internet+ Zhiqiang Li, Fei Zeng, Cheng Yan et al.-

Belt Conveyor - Designing Your Modular Belt Conveyor

2019.5.21 Step 4: Calculate allowable belt strength. Step 5: Check belt selected is suitable. Step 6: Calculate sprocket and drive shaft requirements. Step 7: Calculate power needed to drive the belt. Deciding on the right specification of modular conveyor belt can be a complicated task as there are so many parameters to consider.

Understanding Conveyor Systems - Thomasnet

2023.9.12 Conveyor Systems are mechanical devices or assemblies that transport material with minimal effort. While there are many different kinds of conveyor systems, they usually consist of a frame that

What Is Conveyor System? - Working, And Types

2021.10.2 A conveyor system may use a belt, wheels, rollers, or a chain to transport objects. A conveyor system is a common piece of mechanical handling equipment that moves materials from one location

Pouch conveyor drive system dynamics International Journal of ...

2020.8.29 The design of drive systems for conventional conveyors utilises a planar frictional contact between the pulley and belt, with no regard for viscoelastic or indentation effects (DIN 22101 2011). For a pouch system, the curvature of the belt surface and drive wheel seen in Fig. 2 b, coupled with the viscoelasticity of the conveyor belt cause the

DESIGN AND SELECTING THE PROPER CONVEYOR-BELT

The area of the section “S” may be calculated geometrically adding the area of a circle A1 to that of the trapezoid A2. The value of the conveyed volume 1VT may be easily calculated using the formula : where : IVT = conveyed volume at a conveyor speed of 1 m/s. Angles of surcharge, repose, and material fluency: 5.1. Belt speed:

The Ultimate Guide to Conveyor Systems - Plant Automation

You can find belt drive in a variety of places on a conveyor, depending on the design. Most belt conveyors use AC motors to power the pulleys that move the belts. Types of Conveyor Systems. There are several different conveyors. The three most prevalent types are overhead, belt, and roller, with overhead being the two-fold form.

[PDF] An Integrated Inspection System for Belt Conveyor

DOI: 10.5220/0006369101900200 Corpus ID: 21842420; An Integrated Inspection System for Belt Conveyor Rollers - Advancing in an Enterprise Architecture @inproceedings{Nascimento2017AnII, title={An Integrated Inspection System for Belt Conveyor Rollers - Advancing in an Enterprise Architecture}, author={Richardson

Conveyor Belts Systems: Design Manufacturing - Beumer

Conveyor belts are the first choice for moving both raw materials and processed materials quickly, often covering great distances and rough terrain in the process. Their robust design ensures that the conveyor system is economical compared to alternative solutions. They also typically expend less energy and less CO2, in addition to lower levels ...

RU%HOWV9LD6LPXODWLRQ0RGHOOLQJ0HWKRGV

A belt conveyor system is one of many types of conveyor systems used to transport materials. A belt conveyor system usually consists of two or more pulleys in a closed loop to drive the belt in circular rotation. Belt conveyor system is commonly used for transporting bulk materials such as grain, salt and sand. Belt deflection is said to have ...

(PDF) CONVEYOR HANDBOOK anton fitriyadi - Academia

Belt Conveyor Design and Analysis. 2014 •. Serpil Kurt. For handling of partial or continuous goods, belt conveyors are very efficient way. Belt conveyors are used in mining, iron and steel plants, thermal power plants, ore, coal, limestone, sinter transmission, automotive and the other sectors. There are several factors that have to be taken ...

Conveyor Systems Types, Specifications and Selection

4: Conveyor system design. Owing to their large scales and integration into different factory processes, conveyors systems are often relatively complex in their design and construction . Fortunately, the modular nature of many conveyor components makes even complex and long conveyor systems easily achievable.

>> Next: Costo Del Molino De Materiales De Construcción

Artículos Relacionados

- para comprar la maquina de fabricacion de yeso carton

- fabricantes de trituradoras de mina sudafrica

- mesto trituradora de mandíbula

- smill trituradora en la mexico

- para que sirve un espumante en flotación

- equipos de minería de oro para la venta nz

- especificación de trituradoras de mineral de oro en méxico

- molinos de alta velocidad no utilizados en la determinación del agua es

- en veracruz petrolera

- nuevo precio trituradora de cono de 24

- placas desgaste piezas

- repuestos para incluyendo

- trituradora de archivos

- trituradora para la venta en ecuador

- fabricación de la trituradora de mineral de hierro

- molino de bolas pólvora para venta

- descargar solucionario hibbeler dinamica 12 edicion gratis pdf

- trituradora de impacto tmi

- maquinaria minera de mármol

- trituradora madera engine

- para maquina de fabrica de oleo

- trituradora rocas rodillos

- móvil de asfalto planta de mezcla

- pequeno molino de bolas de oro para el procesamiento del mineral

- trituradora de mandibula dibujo

- indian wet grinder in toronto

- molino de bolas con fabricacion de revestimientos portatil

- rolo triturador genovese precios

- molinos de bolas en venta usados en me ico

- albita fabricante de equipos de procesamiento